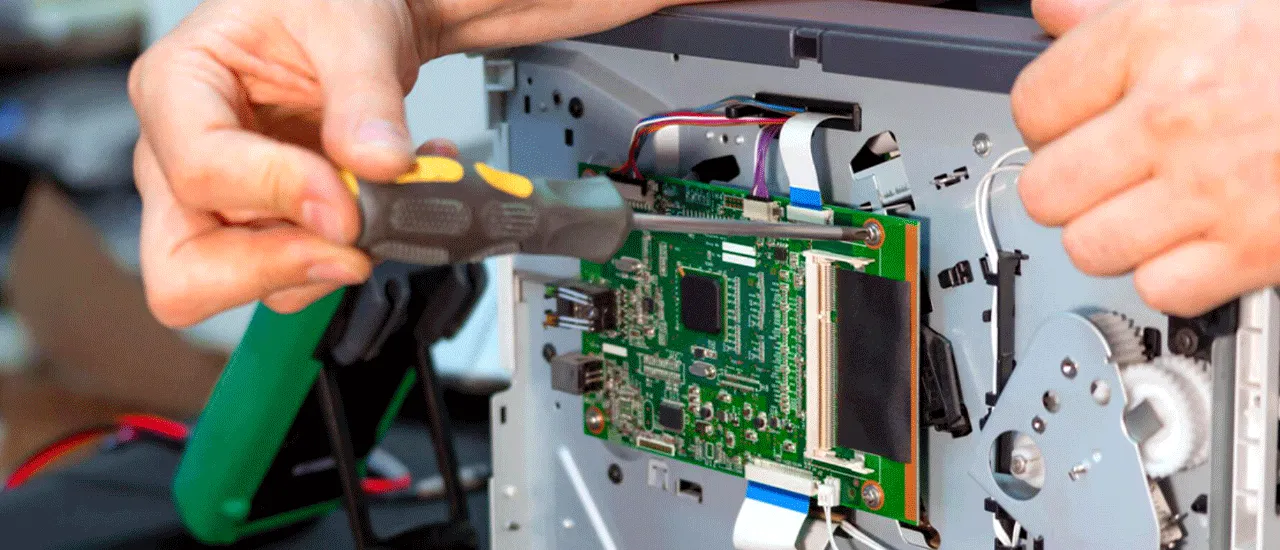

Electro-mechanical Assembly

From PCB Assembly To Complex Systems

- PCB Fabrication & Box Build Assembly

- System Integration & Functional Testing

- Electronics & Mechanical Parts Sourcing

- Custom Cable/Wire Assembly

- Small to Medium Volume Production

- ISO9001:2015, ISO 13485:2016 Certified & UL Listed

What Is an Electro-mechanical Assembly?

A basic electromechanical device is composed of three main systems: the electrical circuit, the electrical coupling system, and the mechanical system. The scope of electromechanical systems is extensive, covering components like input/output devices, lights, PCBs, wires and cables, pneumatics, actuators, gears, sensors, microprocessors, switches, hydraulics, digital signal processors (DSPs), enclosures, and DIN rails. By integrating and combining electrical and mechanical components, we enable systems that can sense, process, and respond to variable inputs and conditions.

Our electromechanical assembly services involve the seamless integration of electronic and mechanical parts into a fully functional system. Using state-of-the-art assembly equipment, we assemble and electrically connect components such as electronic and optoelectronic parts, substrate PCBs, wires, connectors, and other critical components, all in accordance with the provided electrical design.

Key Elements in Electromechanical Assemblies

Electromechanical Assembly From Design to Assembly

PCB Miniaturization

Through Hole Technology (THT) requires more space on the PCB for component attachment, limiting design flexibility. In contrast, Surface Mount Technology (SMT) allows for more compact, lightweight, and efficient circuit board assemblies. This makes SMT the ideal choice for applications like wearable and portable devices, where space-saving and performance are essential.